BUNKER SURVEY | ON / OFF HIRE SURVEY | DRAFT SURVEY | ULLAGE SURVEY | 3RD PARTY INSPECTION SERVICE

Bunker Survey , On / Off hire survey CONDITION and BUNKER Survey

On- Hire, Off- Hire, Pre & Post Bunker Delivery Survey

The on/off hire bunker & condition surveys are most frequently required to be performed combined but we also perform either just on/off hire bunker survey or on/off hire condition survey separately. It is also common to be performed jointly with the other interested part, being one company appointed by Owners and other by Charterers.

This inspection is conducted to the vessel at the beginning and/or end of the chartering and aims at checking the overall condition of the vessel.

The on/off hire condition survey is an inspection of vessel’s holds, main deck, cargo working areas and external shell plating. It is performed in order to identify any damage present prior to the vessel going on/off hire.

By doing it repetitively for many years, our surveyors became experts in analysing a vessel. The eyes of an experienced professional inspect every bulkhead, ladder, pipe, corrugate, lower and upper hoppers, bilge, tank top plating, manhole, hatch coaming, hatch covers and many other structures.

MARINE SERVICE’s Marine & Cargo Surveys start the attendances of on/off hire condition surveys at berthing time, before the commencement of loading operation, or, at the end of a discharging operation, in order to inspect the holds without cargo inside to be more precise.

Our company details the findings of the inspection in the Survey Report that includes the anomalies found, general particulars of the vessel, relevant documents and a photography list showing the actual condition of the vessel. MARINE SERVICE works to issue the Survey Report within three days after the completion of inspection.

This survey is compared with the previous condition survey carried out to the vessel, in order to determine if new damage have occurred to the vessel from cargo operations and/or stevedores damage.

The bunker survey is required in order to calculate the exact amount of bunkers on board at the time of vessel’s delivery/re-delivery.

The vessel is delivered by the owner to the charterer, in case of On-Hire. At this time, usually, the Master issues a Delivery Certificates stating the place, time, parties involved and total amount of bunkers on board.

In case of re-delivery, the vessel is redelivered by charterer to the owner by the end of the chartering (Off Hire), when it is issued the “Redelivery Certificate”.

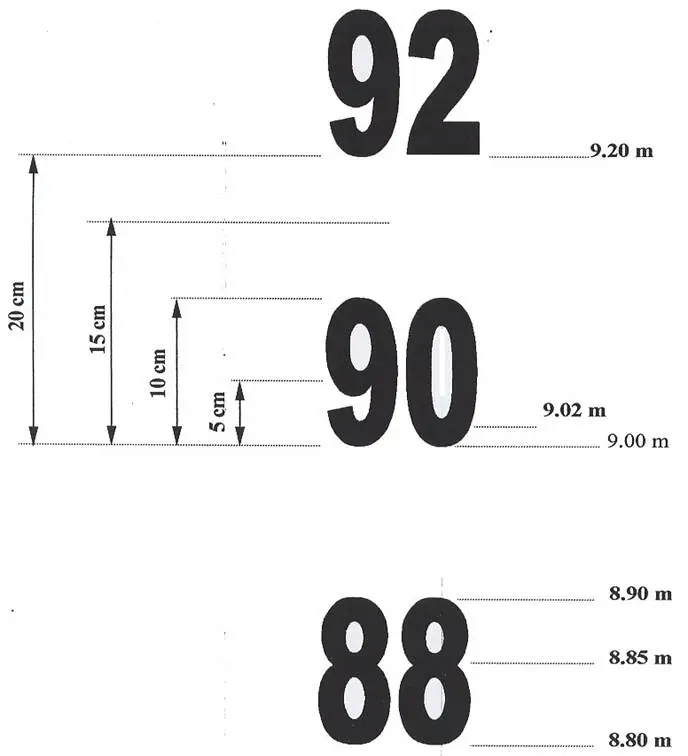

The Surveyor carry out sounding of all bunkers tanks and performs corrections of soundings to vessel’s trim and heel to find out the volume in tanks. Then it is applied with corrections for temperatures and specific gravity, in order to determine the actual quantity of bunkers on board at the time/place of survey. The Surveyor checks vessel’s consumption, as per perusal of engine log book and chartering details, to establish the amount of bunkers remaining on board at Delivery/Redelivery time.

Once we are assigned for Chittagong or Mongla port for carrying our off-hire bunker or off hire bunker and condition survey, we always appreciate that Principals/ charterer will provide the following information.

- Name of owner

- Name of charterer

- Redelivery place

- Any other special instruction

- The names of the charterer and owner are to be entered in the re-delivery certificate.

Draft Survey And Draft Survey Dispute Resolution

The Draft Survey is a technique based on Archimedes’ principle to calculate the weight of cargo loaded or unloaded to or from a ship from measurements of changes in its displacement. HDUM conducts draft survey of ocean vessels and local barges on a regular basis, as required by our clients. We perform job on behalf of Owners, Charterers or any other interested party.

It is top of our priority list to give quality services by using our own calibrated equipment, we assure that the findings are as accurate as possible. We also assist as third party in case of draft survey disputes in finding resolution.

Project cargoes are cargo with very high value. HDUM has good experience in handling project cargo for clients. Our surveyors will assist in reviewing and approving load/discharge procedures, preloading/discharge inspection of project cargo, assist in proper lashing of project cargo on board for safe shipment.

Ullage Survey

Ullage survey method is used to determine the amount of liquid cargo such as crude oil, petroleum products, chemicals and similar loaded or discharged on tanker ships. In short, it is a weight determination method. This technique is based on measuring the empty space above the load in the tanks and making some static calculations. In this way, the weight of the cargo carried by the ship is found.

The measurement of the distance (ie the space) between the surface of the liquid in a tank and the top of the inner surface of the tank is called the ullage method. There are ullage tables on the ships. These tables are generated relative to the internal volume of a tank measured from a reference point. The reverse of the Ullage method is the sounding method (ie depth measurement method). In this method, the depth of liquid in a tank is measured from the liquid surface to some reference points at the bottom of the tank.

Ullage expression refers to the free space left in the tanks after the liquids are loaded into the tank. In general, a space is left in oil tankers for the oil to heat up and expand. This void is actually ullage. Petroleum products can expand with atmospheric temperature changes. For this reason, tanks are normally loaded with 98 percent capacity.

In short, ullage is a widely used calculation method in industrial tanks used to store liquids or tanks used to transport liquids in maritime transport. According to the legal regulations in force, pressure tanks on ships cannot be more than 98 percent full, with exceptions.

In some cases, the ullage (space) in a ship’s tanks is related to the ship’s stability. This is all about the ship’s management and management technique. Here, too, the effects of the fluctuation of the liquids in the tanks on the balance of the ship are calculated.

Ullage survey services are also provided by MARINE SERVICE within the scope of ship surveillance services.is. In this way, enterprises learn the amount of load in the tanks reliably and accurately.

Independent Insights for Optimal Vessel Performance with Fresh Perspectives, Proactive Solutions

Understanding Third-Party Inspection for Ships

Third-party inspections involve an independent and unbiased evaluation of a vessel’s condition and operations. These inspections are crucial for identifying potential issues that internal auditors might overlook due to their familiarity with daily operations or relationships with the superintendent or in-charge. MARINE SERVICE‘s third-party inspections are meticulously designed to uncover loopholes, defects, or shortcomings that may not be apparent due to “normalization of deviance” within the organization.

“Normalization of deviance” refers to a situation where people within an organization become so accustomed to deviations or substandard conditions that they no longer perceive them as abnormal, despite being outside acceptable norms or standards.

The MARINE SERVICE‘s Difference in Third-Party Inspection

Fresh Eyes:MARINE SERVICE‘s inspectors bring a fresh perspective, identifying issues that internal employees might miss due to their habitual environment.

Expertise and Impartiality:Our inspectors provide unbiased, objective assessments, free from internal dynamics or organizational influences.

Proactive Issue Resolution:Third-party inspections help anticipate and address potential issues early, ensuring compliance with industry standards and enhancing vessel longevity and safety.

Comprehensive Assessment:Our expertise allows us to assess every aspect of your vessel’s operations, providing detailed reports to proactively address potential issues within a 3-6 month time frame.

Enhanced Safety and Performance:We prioritize the utmost performance and safety of your vessels, helping you maintain high standards through early issue identification and resolution.

Cost Efficiency:By identifying potential issues early, our inspections help avoid costly repairs and downtime, ultimately saving money and improving operational efficiency.

Why Partner with MARINE SERVICE

Your Unbiased Eye for Unmatched Vessel Safety and Performance. Trust our expertise to navigate your operations towards excellence.